The Vacuum lyophilizer dryer system is divided into four parts, which are composed of a refrigeration press, a vacuum system, a heating system, and a control system. It is composed of a drying box, condenser, machine, vacuum pump and valve, and electrical control components. Suitable for blast freezer cold room, vaccine storage room, containerized cold storage room, industrial refrigeration cold room, etc.

一、Product description

1.Our Vacuum lyophilizer is used in the field of optimized freezing and drying process.

2.The frozen and dried products have the high value, hence, the design of the freezing drying is in terms of safety to the greatest extent. The humanity design applied in the freeze drying machine ensures the safety of the user and environment.

3.The mature design technology is put into the freeze drying machine which is produced with the high quality material and component accepted in the world widely. At the same time, the advanced high-tech process is utilized in the freeze drying machine

4.Our freeze drying machine design and manufacture Under FDA&cGMP Standard.

二、Working principle

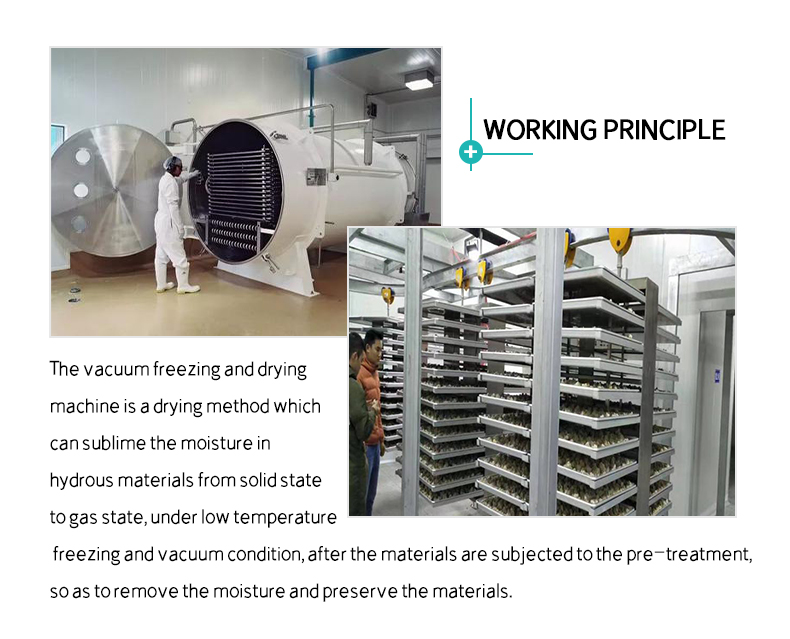

The vacuum freezing and drying machine is a drying method which can sublime the moisture in hydrous materials from solid state to gas state, under low temperature freezing and vacuum condition, after the materials are subjected to the pre-treatment, so as to remove the moisture and preserve the materials.

三、Detailed description

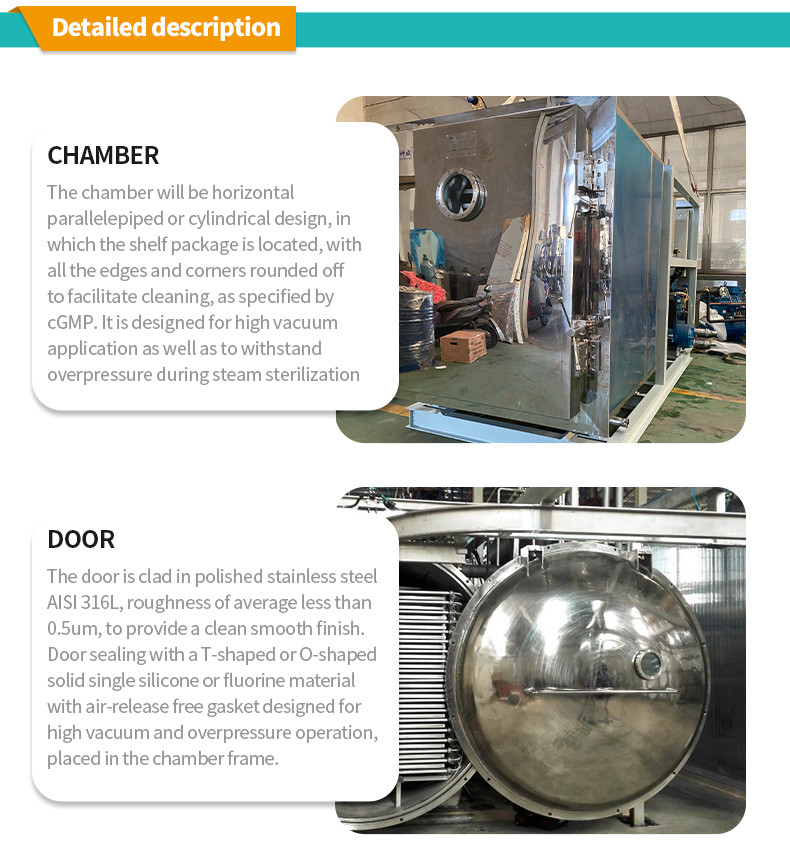

CHAMBER

The chamber will be horizontal parallelepiped or cylindrical design, in which the shelf package is located, with all the edges and corners rounded off to facilitate cleaning, as specified by CGMP. It is designed for high vacuum application as well as to withstand overpressure during steam sterilization.

DOOR

The door is clad in polished stainless steel AlSI 316L, roughness of average less than 0.5um, to provide a clean smooth finish. Door sealing with a T-shaped or O-shaped solid single silicone or fluorine material with air-release free gasket designed for high vacuum and overpressure operation, placed in the chamber frame.

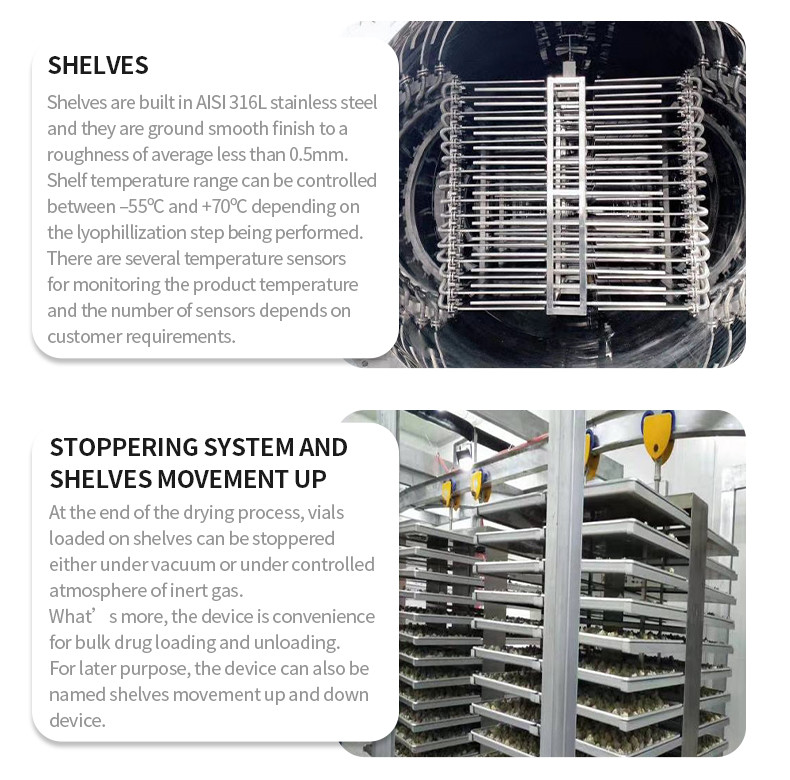

SHELVES

Shelves are built in AlS| 316L stainless steel and they are ground smooth finish to a roughness of average less than 0.5mm. Shelf temperature range can be controlled between -55°C and +70°C depending on the lyophillization step being performed. There are several temperature sensors for monitoring the product temperature and the number of sensors depends on customer requirements.

STOPPERING SYSTEM AND SHELVES MOVEMENT UP

At the end of the drying process, vials loaded on shelves can be stoppered either under vacuum or under controlled atmosphere of inert gas. What's more, the device is convenience for bulk drug loading and unloading. For later purpose, the device can also be named shelves movement up and down device.

CONDENSER

Ice condenser assemblv suitable for vacuum and steam sterilization over-pressures with horizontal or vertical cylindrical shape or rectangular shaped, made of AIS| 316L stainless steel.

REFRIGERATING SYSTEM

Refrigerating system is used to cool the thermal fluid for the shelves during the freezing, and eventually during evacuation and drying sequences, and to cool the condenser coil during the evacuation and the drying sequences.

VACUUM SYSTEM

The vacuum pump group consisting of vacuum drying and its related valve during the freezing and drying operation. The inside vacuum is connected with refrigerating system through AISI304L stainless steel. The automatic and pneumatic butterfly is used between the vacuum system and condenser to make the vacuum system isolate the freeze dryer.

四、Optional equipment

CIPSYSTEM

Using suitable rotary or fixed sprayers and fixed wide-angle nozzles to sprinkle the cleaning water to the surface of shelves and chamber. Moving up and down the shelves is helpful for washing in the process.

SIPSYSTEM

Sterilizable freeze dryers offer the most adequate solution to process sterile products, ensuring the lowest contamination risk.