Comparison between XPS Panel Cold Room and PU Panel Cold Room

Jan 21, 2020|

Jan 21, 2020| View:265

View:265Comparison between XPS Panel Cold Room and PU Panel Cold Room

Main features of a.XPS Panel Cold Room extruded foam board

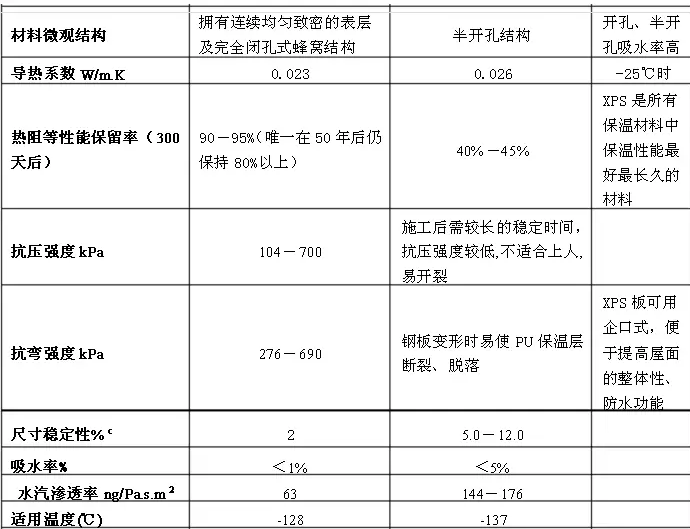

1. Excellent heat preservation performance: as a kind of heat preservation and insulation material, XPS Panel Cold Room extruded insulation board has excellent heat preservation and insulation performance. Its thermal conductivity is 0.028 w / m.k when the test temperature is 25 ℃; its thermal conductivity is only 0.023 w / m.k when the test temperature is - 25 ℃; its thermal conductivity is 0.026 w / m.k when the test temperature is - 25 ℃; therefore, its thermal conductivity is 0.026 w / m.k when the test temperature is - 25 ℃ At low temperature, the thickness of XPS Panel Cold Room extruded board is almost the same as that of PU Panel Cold Room, but the extruded board can be even thinner.

2. Extraordinary durability: XPS Panel Cold Room extruded board is the only one of the thermal insulation materials that still maintains more than 80% of the thermal insulation performance after 50 years.

3. Excellent water resistance: the volume water absorption of the XPS Panel Cold Room Extrusion board is less than 1%, and the water vapor permeability coefficient is 3ng / (pa.m.s).

4. Excellent compressive performance: XPS Panel Cold Room extruded board is a kind of light-weight and high-strength board. The compressive strength can be as high as 350kPa when the density is not more than 40kg / m3.

5. High-quality environmental protection products: the extruded insulation extruded board has stable chemical properties, no volatilization of harmful substances, no decomposition or mildew, and good corrosion resistance. In the production process, no harmful gas is produced, and the production process also embodies the concept of environmental protection. The solid waste generated can be recycled and treated, which is an environmental protection product that can be recycled.

2、 Performance comparison of XPS and PU materials in cold storage

In the selection of thermal insulation materials for cold storage, designers and owners often only pay attention to some physical properties of thermal insulation materials themselves, such as thermal conductivity, oxygen index, etc., while ignoring that thermal insulation is a systematic solution in the actual project. No matter how good a material is, if it is not equipped with a good solution, it will not achieve good results. A perfect scheme determines the heat flow rate of the enclosure and the energy consumption of the cold storage. That is to say, the better the long-term effect of the heat preservation scheme, the smaller the energy consumption of the cold storage and the lower the comprehensive cost. Through the above analysis, we can focus on the following aspects:

The so-called design thermal conductivity is based on the determination of the thermal conductivity of materials multiplied by a design safety factor. The design coefficient is because the thermal conductivity of thermal insulation materials will be improved and the thermal resistance will be reduced relatively under the influence of humid environment and water vapor infiltration in the cold storage for a long time. Its size depends on the material of the thermal insulation material itself, closed porosity, microstructure, water absorption, and other factors. The design thermal conductivity of materials with low thermal conductivity is not the lowest. When choosing thermal insulation materials, the design thermal conductivity of thermal insulation materials in the actual application environment should be compared.

The relative humidity of cold storage is more than 85%, so the effect of heat preservation material is very important under high humidity.

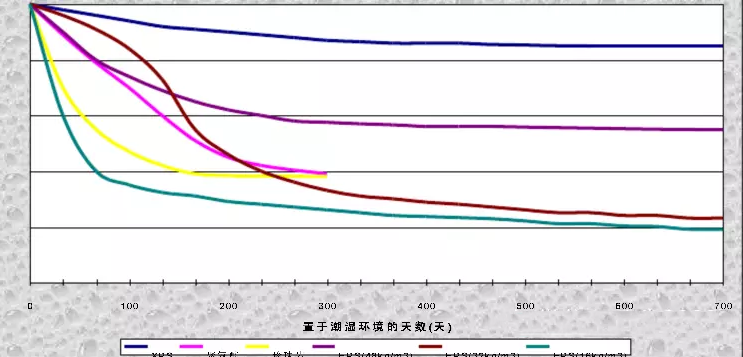

The figure below shows the thermal resistance retention rate of various insulation materials at 70% relative humidity. It can be seen from the figure below that at 70% relative humidity, the thermal insulation effect of all thermal insulation materials has decreased, the thermal insulation effect of rigid polyurethane is about 40% of the initial value, and that of extruded polystyrene board is as high as 85%.

2. Water absorption: water absorption is an important index affecting the heat preservation effect. When the material absorbs water and extrudes the gas in the material, water occupies the original space. The thermal conductivity of water is 1W / m · K, which increases the thermal conductivity of the thermal insulation material. Therefore, the greater the water absorption, the worse the insulation effect.

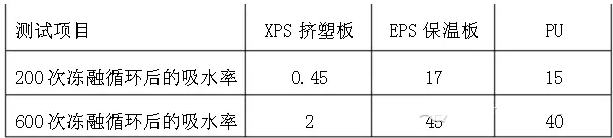

3. The difference of water absorption between the field foaming PU Panel Cold Room and the factory produced XPS Panel Cold Room is more than twice. The water absorption is a key factor for the thermal insulation material. The products with high water absorption will cause fatal changes in the aging, deformation and thermal insulation performance of the product. The freeze-thaw cycle will cause the structural damage of the material due to the high water absorption, thus aging, deformation and greatly reducing the service life! This is also the reason why the insulation effect of the PU Panel Cold Room is greatly reduced after a period of operation as insulation material in the system application!

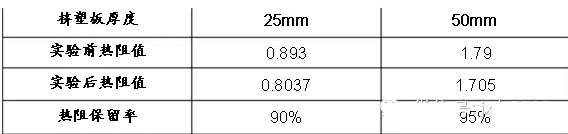

1) The heat preservation effect after freeze-thaw cycle in the use of cold storage, there is a process of steam transfer from high temperature to low temperature and freeze-thaw cycle in the heat preservation material, in the case of freeze-thaw alternation, the thermal resistance of the heat preservation material will decrease to varying degrees, the following table is the thermal resistance retention rate of extruded polystyrene board after 100 freeze-thaw cycles. However, the retention rate of thermal resistance of field foamed Pu is usually about 40-50% after 300 days.

4. Durability: With the passage of time, the insulation and flame retardancy of PU Panel Cold Room are reduced after the components are volatile, and the material becomes brittle and powdered, which is the reason why the power consumption of the cold storage with PU insulation increases gradually after one or two years of use. Because of its stable chemical structure and physical structure, XPS Panel Cold Room insulation board has extraordinary durability. Its thermal insulation performance changes little with time. Even after 50 years, its thermal insulation performance remains more than 80% of the initial value, which can still maintain excellent thermal insulation performance in the cold storage application after repeated freezing and thawing.

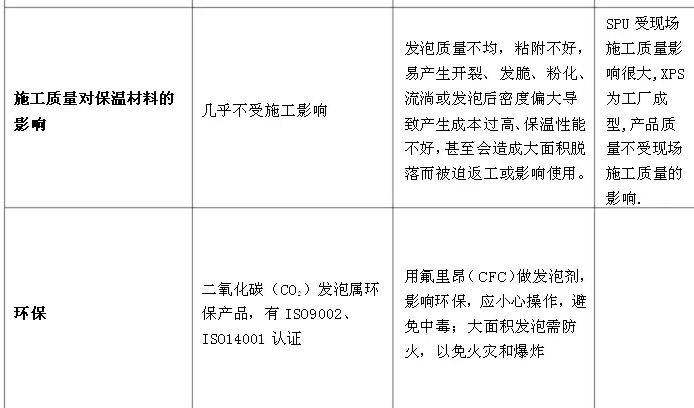

5. Environmental protection: carbon dioxide (CO2) for the foaming agent of the extruded board is an environmental protection product with ISO9001 and ISO14001 certification. Freon (CFC) is used as a foaming agent for foamed polyurethane, which affects the environmental protection, so it should be handled carefully to avoid poisoning; large-area foaming needs fire prevention to avoid fire and explosion, which has occurred many times in the actual project, so we should take precautions.

6. Fire resistance: in order to meet the fire protection requirements of the design, polyurethane will not only greatly reduce its heat preservation performance after adding flame retardant, but also the flame retardant added in polyurethane will volatilize with the passage of time, which will reduce the fire resistance, resulting in the polyurethane in the construction process and prone to fire. Many refrigerators have occurred several times during the polyurethane spraying construction A small fire. The fireproof performance of the extruded board can reach Class B1 and B2, fully meet the design requirements, and solve the customer's worries.

7. Construction difficulty: a good thermal insulation system requires not only reasonable design in the early stage, but also suitable materials and construction technology. If the early design and materials are perfect, but the construction technology is complex or there are too many influencing factors, the actual effect of the thermal insulation system will be far from the expected. The extruded board insulation system can be directly assembled on-site according to the design, not affected by the environment, and the construction is simple and fast. If polyurethane foam is used, it needs to be foamed on-site, affected by weather, environment, wind speed, temperature (15-30 ℃), humidity, and the quality of operators, and the temperature is high when the eruption is just completed, which is easy to produce hollow; after cooling, it is easy to produce hollow, which is difficult to ensure the quality.

In addition, the following table is attached for comparison of performance indexes of XPS and Pu:

Note: the data in the table are drawn from the American Standard ASTM, "code for thermal design of civil buildings" GB50176-93, "insulation extruded polystyrene foam plastic (XPS)" GB/T10801.2-2002.