Differences among fresh storage, Polyurethane Cold Room, freezing storage and air conditioning storage

Feb 27, 2020|

Feb 27, 2020| View:193

View:193Differences among fresh storage, Polyurethane Cold Room, freezing storage and air conditioning storage

Fresh Storage

The storage temperature of the fresh-keeping storehouse is generally 0 ℃ ~ 5 ℃, which is mainly used for fresh-keeping, that is, to keep the original quality and freshness of agricultural products in a long time, the living body of agricultural products should not die as much as possible, the cells should be in a dormant state in the process of cold storage, so as to reduce the loss of nutrition and maintain the fresh quality.

This is generally used in fruits and vegetables. Nowadays, the fruit and vegetable industry is centralized planting. In the process of transportation and sale, it is inevitable to use cold storage to maintain the nutrition of fruits and vegetables.

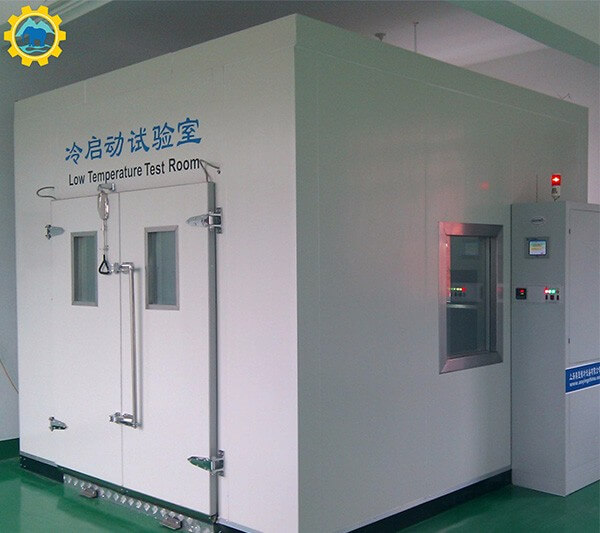

The temperature of polyurethane cold room is generally - 15 ℃ ~ - 18 ℃. Generally, the food is put into the cold storage step by step irregularly. After a period of time, the temperature of the cold storage reaches - 18 ℃, and it is also irregular and irregular to pick up the goods. There is no specific requirement for this "period of time", which is a typical cold storage.

For example, meat and aquatic products have higher storage temperature requirements, so as to keep the internal class from deterioration. And in the process of sale, they are also taken out and stored irregularly. Generally, the refrigerators in large supermarkets are polyurethane cold room.

Cold storage

The storage temperature of refrigerated low temperature storage is generally - 22 ~ - 25. It uses a variety of refrigeration equipment, that is, artificial refrigeration, to keep a certain low temperature in the room. Many foods, such as ice cream and seafood, need to be stored at - 25 ℃ to keep them from deteriorating. For example, if ice cream is stored at less than - 25 ℃, its flavor will be gone; the taste and taste of seafood will be much worse.

The characteristics of the cold storage are as follows: the food is put into the cold storage step by step irregularly. After a period of time, the temperature of the cold storage reaches - 25 ℃. There is no special cold storage design process and technical requirements for this period of time. There are strict requirements for the temperature of the cold storage. It is a typical cold storage between - 22 ℃ and - 25 ℃.

Compared with the fresh-keeping storehouse, the function mechanism of the frozen storehouse is very different. Too low temperature will cause the cell death of food such as meat seafood, and the freshness will be greatly affected. Therefore, the lower the temperature, the better the storage of fruits and vegetables.

Modified atmosphere storage

Controlled atmosphere storage is the most advanced storage method of fruits and vegetables. On the basis of the fresh-keeping storehouse, it increases the regulation of gas composition. By controlling the temperature, humidity, carbon dioxide, oxygen concentration and ethylene concentration in the storage environment, it can inhibit the respiration of fruits and vegetables, delay their metabolism process, better maintain the freshness and commerciality of fruits and vegetables, and extend the storage period and fresh-keeping period (sales shelf life).

Generally, the storage period of the fruits and vegetables stored in the air-conditioned warehouse can be prolonged by 0.5-1 times as long as that in the ordinary refrigerated warehouse; the fruits and vegetables stored in the air-conditioned warehouse can first "wake up" from the "dormancy" state after they leave the warehouse, which makes the fresh-keeping period (sales shelf life) of the fruits and vegetables after they leave the warehouse be prolonged by 2-3 times as long as that in the ordinary refrigerated warehouse.

Controlled atmosphere storage can create the best storage environment of fruits and vegetables by changing the gas composition and relative humidity of the storage environment under the suitable low temperature conditions. Its effect is shown in the following aspects:

(1) Low oxygen (generally 3% - 5%) and proper CO2 concentration can effectively inhibit respiration, reduce the loss of nutrients in fruits and vegetables, inhibit the growth and propagation of pathogens, and control the occurrence of some physiological diseases;

(2) The ethylene in the storage environment was removed to inhibit the ripening of fruits and vegetables and delay the ripening and aging process;

(3) Increase the relative humidity in the environment gas, reduce the transpiration of fruits and vegetables, so as to achieve the purpose of long-term storage and preservation of fruits and vegetables.

Next, I'd like to introduce the most commonly used polyurethane cold room board, polyurethane cold room board

Library board model:

① Thickness of polyurethane cold storage board: 100 mm, 125 mm, 150 mm, 175 mm, 200 mm optional.

② Polyurethane cold storage plate length: match the actual data.

③ Width of polyurethane cold storage board: standard width is 1000mm

④ Polyurethane cold storage board surface automatic film, to ensure the board surface clean and beautiful.

⑤ Polyurethane cold storage board surface automatic film, to ensure the board surface clean and beautiful.