Common Faults And Causes Of Air Cooled Cold Room

Mar 23, 2020|

Mar 23, 2020| View:194

View:194Common Faults And Causes Of Air Cooled Cold Room

1. All refrigerants in the refrigeration system of the air cooled cold room leak, for the following reasons:

It is not used for a period of time, and only when it is used can leakage be found or the use process is found to be gradually cold.

Due to the sudden rupture of the system pipeline, the refrigerant leaks out quickly.

Judgment method: the compressor is easy to start (when the compressor parts are not damaged), the suction pressure is vacuum, the exhaust pressure is very low, the exhaust pipe is cold, and the water flow sound of liquid can not be heard in the evaporator.

Elimination method: check the whole machine, mainly check the leaky parts. After finding the leakage part, it can be repaired according to the specific situation, and finally vacuumized and filled with refrigerant.

2. Expansion valve block of refrigeration system of air cooled cold room:

Intermittent refrigeration: the refrigeration starts normally. After a period of time, the whole surface of the expansion valve begins to frost. The evaporation temperature is below 0 ℃, and the water accumulates at the expansion valve hole, gradually blocking the valve hole. Then frosting occurs at the evaporator, and no sound of air flow can be heard. The suction pressure is in a vacuum state. The expansion valve is heated by hot water, which is the ice layer at the valve hole melts and can be cooled normally.

Fault analysis:

Improper drying of main parts in refrigeration system;

The whole system is not completely vacuumized;

The moisture content of refrigerant exceeds the standard.

Troubleshooting: put a filter with moisture absorbent (silica gel, anhydrous calcium chloride) in the refrigeration system, filter out the water in the system, and then remove the filter.

3. Dirty and blocked filter screen of expansion valve of refrigeration system:

When there are more coarse powdery dirt in the system, the whole filter screen will be blocked and the refrigerant will not pass through, resulting in no refrigeration. Touching the filter with your hand is cooler than usual.

Troubleshooting: remove and clean the filter, dry it, and install it into the system again.

4. Leakage of refrigerant in temperature sensing bag of expansion valve:

After the temperature sensing agent in the temperature sensing package of the expansion valve leaks, two forces under the diaphragm push the diaphragm upward, which means that the valve hole is closed, and the refrigerant in the system cannot pass, resulting in no refrigeration. At this time, the expansion valve is not frosted, the low pressure is vacuum, and the air flow sound can not be heard in the evaporator.

Judgment method:

Loosen the inlet of the expansion valve to see if there is refrigerant ejecting. If yes, close it quickly.

Open the expansion valve port to see if refrigerant is ejected. If not, it means it is blocked.

Troubleshooting: shut down and close the stop valve, remove the expansion valve to check whether the filter screen is blocked, if not, blow the inlet of the expansion valve with the nozzle to see whether it is ventilated. It can also be visually inspected or disassembled for inspection and replaced in case of damage.

5. Cold storage of cold water condenser:

The cold water valve is not opened or too small, and the water inlet pressure is too low;

Failure of water regulating valve;

The scale on the condenser tube wall is thick.

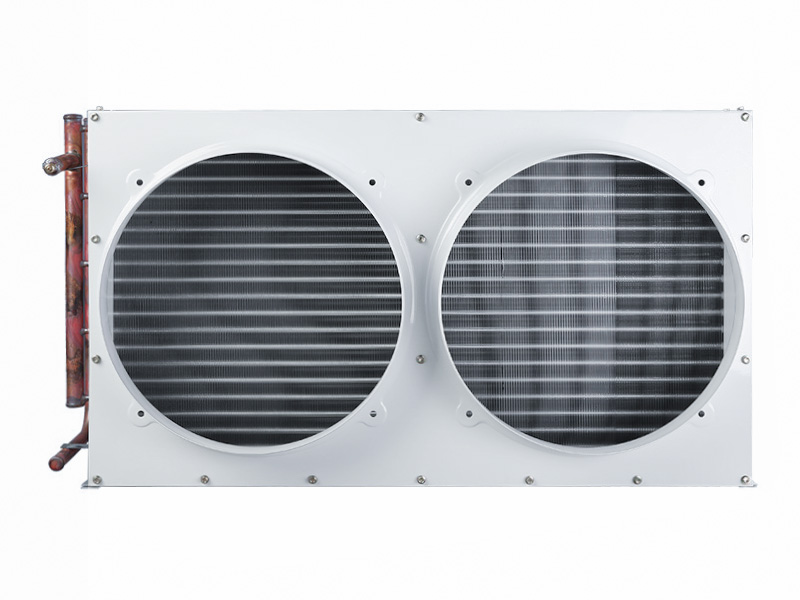

Air cooled cold room: feel whether there is wind blowing out by hand; use wire brush to clean the surface dust of air-cooled condenser;

Water cooled cold storage: temperature difference of side water inlet. Check the cooling water volume of the water-cooled condenser and remove the scale.

6. Too much refrigerant is charged into the system:

Too much refrigerant will cause the exhaust pressure to rise significantly beyond the normal value. It can be shut down and discharge the excess refrigerant out of the system in the high-pressure exhaust port.

7. Residual air in the system:

There is air circulation in the system, which will cause high exhaust pressure, high exhaust temperature, hot exhaust pipe, poor refrigeration effect. Soon after the compressor runs, the exhaust pressure exceeds the normal value, forcing the pressure relay to act. It can be shut down and put air at the highest place of condenser.

8. Shutdown due to low suction pressure:

When the suction pressure in the system is lower than the set value of the pressure relay, it will be cut off due to electric shock.

Discharge method: refrigerant leakage; system is blocked.

9. Shutdown caused by too high pressure during operation of compressor:

The common causes of condenser shutdown in air cooled cold room are as follows:

Cold storage fan is not on;

Fan motor damaged;

Fan reverse;

High ambient temperature;

The cooling fins of the condenser are blocked by oil and dust to prevent the air from flowing.

10. Shutdown due to electrical failure:

Common reasons are: temperature controller regulation failure or improper installation of temperature sensing package. The temperature controller can be removed to maintain its electric shock, adjust and adjust the position of the temperature sensing package.