Design And Selection Knowledge Of PU Panel Cold Room

Jan 03, 2020|

Jan 03, 2020| View:213

View:213Design And Selection Knowledge Of PU Panel Cold Room

1、 PU panel cold room is generally divided into the indoor type and outdoor type

1. Ambient temperature and humidity outside the refrigerator: temperature is + 35 ℃; relative humidity is 80%.

2. Set temperature in cold storage: fresh-keeping cold storage: + 5 ~ - 5 ℃; cold storage: - 5 ~ - 20 ℃; low temperature cold storage: - 25 ℃

3. The temperature of food entering the cold storage: l level cold storage: + 30 ℃; D level and j level cold storage: + 15 ℃.

4. The effective storage volume of the assembled cold storage is about 69% of the nominal volume, which is multiplied by a correction factor of 0.8 when storing fruits and vegetables.

5. The daily purchase quantity is 8-10% of the effective volume of the cold storage.

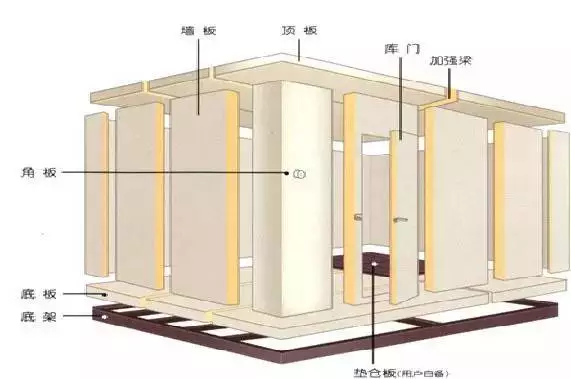

2、 Storage body of PU panel cold room

In general, the spray-painted steel plate is used as the panel, rigid polyurethane foam is used as insulation material, and the storehouse has the characteristics of good rigidity, high strength, good heat insulation performance, and flame retardance.

PU panel cold room is generally connected by eccentric hook type of embedded parts inside the panel wall or foamed and fixed on-site. It has good sealing, convenient installation, removal and handling, a small amount of construction and installation work on-site, labor-saving, good quality, and quick effect. The Pu panel cold room is equipped with an advanced refrigeration unit. The storage capacity is fully matched with the refrigeration equipment. The cooling speed is fast, the power is saved and the energy is saved. All of them are operated automatically, and the operation is safe and reliable. Small assembled refrigerators are widely used. The temperature range of refrigerators is from 5 ℃ to - 23 ℃, and the temperature of specially assembled refrigerators is below - 30 ℃, which can meet the needs of different purposes and can be used in various industries and departments.

3、 Selection of refrigeration equipment for PU panel cold room

The heart of the Pu panel cold room refrigeration equipment is the refrigeration unit. The common model of Pu panel cold room unit is the advanced fluorine machine refrigeration equipment. The fluorine machine refrigeration equipment mostly uses R22 and other new refrigerants which have little impact on the environment. Fluorine machine refrigeration equipment is generally small in volume, low in noise, safe and reliable, high in automation and wide in the application, which is suitable for rural Pu panel cooling room.

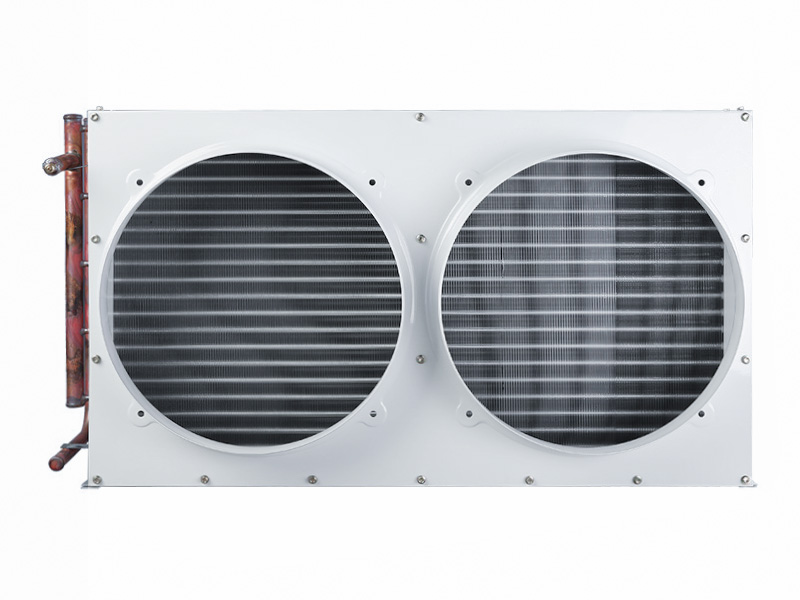

The combination of chiller and condenser used in the PU panel cooling room is often called a refrigeration unit, which is divided into a water-cooled unit and air-cooled unit. The air-cooled unit is the preferred form of Pu panel cold room. It has the advantages of simple, compact, easy installation, convenient operation, less auxiliary equipment and so on. This kind of refrigeration equipment is also easy to see.

The refrigerator of the refrigeration unit is the heart of the refrigeration equipment. The common compression chillers are divided into open type, semi-closed type, and fully closed type. The hermetic compressor has the advantages of small volume, low noise, low power consumption, high efficiency, and energy-saving. It is the first choice model of PU panel cold room, and the air-cooled refrigeration unit mainly composed of the totally enclosed compressor can be made in the form of a split air conditioner and hung on the wall.

At present, the quality of refrigeration equipment imported from developed countries or jointly invested by Chinese and foreign companies is relatively reliable, but the price is more than 50% higher than that of domestic machines, which is more suitable for urban Pu panel cold room refrigeration equipment.

4、 Design points of PU panel cold room

If the temperature of the cold storage is below 0 ℃ (- 16 ℃), 10 channel steel shall be set on the ground (under the storage plate) for overhead, so as to make it naturally ventilated. Pu panel cold room, the temperature in the cold storage is 5 ~ - 25 ℃, the cold storage plates can directly contact with the ground, but the ground should be flat. If high points are required, wooden strips can be placed under the cold storage to enhance ventilation; channel steel can also be placed under the cold storage to enhance ventilation.

5、 Suggestions on design and installation of cold storage engineering

In recent years, the development of cold storage engineering construction is more and more rapid, people's understanding of cold storage is more and more in-depth, from building materials to a variety of cold storage equipment selection is increasingly mature. There are two common construction methods of cold storage engineering, one is assembly cold storage engineering, the other is civil cold storage engineering.

At present, most of the cold storage units choose polyurethane storehouse: the cold storehouse plate is made of polyurethane rigid foam (PU), and the metal material such as plastic coated steel plate is used as the surface layer, which combines the superior heat insulation performance and the good mechanical strength of the cold store plate material. It has the characteristics of long insulation life, simple maintenance, low cost, high strength, and lightweight, etc. it is one of the best materials for the selection of cold storage insulation board. The thickness of the cold storage board is generally 150 mm and 100 mm. Most of the civil cold storage projects use PU polyurethane spray foam as an insulation board.

Freon refrigeration unit, large-scale refrigeration multi-purpose water-cooling unit, and Pu panel cold room multi-purpose air-cooled unit are mostly used in the selection of refrigeration equipment for cold storage engineering; currently, the imported Bitzer refrigeration unit in Germany and my unit in France have stable operation, low energy consumption and low failure rate, which are the first choice for cold storage.

It is very important whether the refrigeration equipment of the cold storage is properly configured. This is because the refrigeration unit with reasonable matching and reliable performance can not only meet the refrigeration capacity and storage process requirements of the product but also save energy and low failure rate. At present, some enterprises and individuals who want to build refrigerators blindly pursue low prices, ignoring whether the configuration and matching of refrigerators are reasonable, resulting in the failure of refrigeration effect after use. The reasonable setting of refrigeration equipment for matching cold storage project may increase investment when building cold storage, but it saves a lot of money and effort in the long run.

The after-sales service of refrigeratory equipment is also very important. The operation and maintenance of refrigeratory equipment and technical service are equally important. Before building cold storage, the majority of enterprises should investigate in many aspects, listen to the opinions of other enterprises on the configuration of refrigeration equipment in the cold storage, and finally determine a practical plan for building cold storage. So that their high starting point, high standards to establish their own cold storage, for their best profits.

With the rapid development of China's economy, refrigeration equipment has entered the supermarket, commerce, agriculture, industry and other fields, which are closely related to our lives. It is unimaginable to live without refrigeration equipment. Due to the rapid development of refrigeration, users often don't know how to choose in the face of many manufacturers and varieties in the market, especially when the demand is large and the investment is large, it increases the difficulty of selection. Henan tens of millions of new building materials Co., Ltd. stands on a just position and provides users with free comparative consultation on technology, quality, performance, price, and other aspects, so that users can judge and choose by themselves. When you want to buy cold storage, we can participate in it and let you quickly find solutions, because we have accumulated a lot of experience in solving such problems.

Selection of PU panel cold room

1、 Use of PU panel cold room

Pu panel cold room is a kind of building that uses the artificial cooling method to make the fixed space reach the specified temperature and easy to store articles.

Cold storage can be widely used in a food factory, dairy factory, pharmaceutical factory, chemical factory, fruit and vegetable warehouse, egg warehouse, hotel, hotel, supermarket, hospital, blood station, army, laboratory, etc. Cold storage is mainly used for constant temperature storage of food, dairy products, meat, aquatic products, poultry, fruits and vegetables, cold drinks, flowers, green plants, tea, drugs, chemical raw materials, electronic instruments, etc.

2、 Classification of PU panel cold room

1. At present, according to the scale of cold storage capacity, the division of cold storage capacity is not unified, generally divided into large, medium and small. The cold storage capacity of large refrigerators is more than 10000t; that of medium refrigerators is 1000-10000t; that of small refrigerators is less than 1000t.

2. According to the design temperature of cold storage, it can be divided into four categories: high temperature, medium temperature, low temperature, and ultra-low temperature.

① The design temperature of general high-temperature cold storage is from - 2 ℃ to + 8 ℃;

② The design temperature of cold storage is from - 10 ℃ to - 23 ℃;

③ The temperature of cold storage is generally from - 23 ℃ to - 30 ℃;

④ Ultra-low temperature quick freezing cold storage, the temperature is generally - 30 ℃ to - 80 ℃.

3. According to the structure category of the warehouse

① Civil cold storage, which is a kind of cold storage built more at present, can be built into single or multi-layer. The main body of the building is usually reinforced concrete frame structure or brick concrete structure. The enclosure structure of the civil cold storage is a heavy structure, with large thermal inertia. The day and night fluctuation of outdoor air temperature and the day and night temperature fluctuation of the external surface of the enclosure caused by solar radiation attenuate greatly in the enclosure structure, so the temperature fluctuation of the internal surface of the enclosure structure is smaller, and the temperature of the storage is easy to be stable.

② The combined plate cold storage is single-layer cold storage. The cold storage plate is a light prefabricated heat insulation plate assembly structure with steel frame, and it's bearing and reconstruction parts are mostly made of thin-walled steel. The inner and outer panels of the scoreboard are made of color steel plates, and the core material of the storyboard is foamed rigid polyurethane or sticker polystyrene foam board. Except for the ground, all components are prefabricated in a complete set in a professional factory according to a unified standard and assembled on-site, so the construction progress is fast and the construction period is short.

③ The earth covered cold storage, also known as the earth kiln cold storage, has a single and continuous arch structure. Generally, it is masonry, and a certain thickness of the loess covering layer is used as the thermal insulation layer. As low-temperature cold storage, the foundation of the tunnel body should be located on the sandstone layer of bedrock which is not easy to frost heave. Because it has the advantages of adjusting measures to local conditions, local materials, simple construction, low cost, solid and durable, it has been greatly developed in Northwest China.

④ The cold storage of the cave is generally built in the rock stratum with hard stone and good integrity. The inner side of the cave is generally treated with lining or shotcreting, and the rock stratum covering thickness of the cave is generally not less than 20 m.

3、 Characteristics and requirements of Pu panel cold room building

Cold storage is a method of artificial refrigeration to keep a certain low temperature in the warehouse. The walls, floors and flat roofs of the cold storage are all laid with a certain thickness of thermal insulation materials to reduce the heat introduced from the outside. In order to reduce the radiation energy absorbed by the sun, the exterior wall surface of the refrigerator is generally painted white or light color. Therefore, the cold storage building is different from the general industrial and civil buildings, with its unique structure.

Cold storage buildings should prevent the diffusion of water vapor and the infiltration of air. When the outdoor air intrudes, it not only increases the cooling capacity of the cold storage but also brings moisture into the warehouse. The condensation of moisture causes the building structure, especially the heat insulation structure, to be damaged by moisture and freezing. Therefore, the moisture-proof and heat insulation layer should be set to make the cold storage building have good sealing and moisture-proof and air insulation performance.

The foundation of cold storage is affected by low temperatures, and the water in the soil is easy to be frozen. Because of the volume expansion of the frozen soil, it will cause the ground rupture and the whole building structure deformation, which will make the cold storage unusable seriously. Therefore, in addition to the effective thermal insulation layer, the low-temperature cold storage floor must be treated under the thermal insulation layer to prevent soil freezing.

A large number of goods should be stacked on the bottom plate of the cold storage, and various loading and unloading and transportation machinery and equipment should be used. Therefore, its structure should be strong and have a large bearing capacity.

In the low-temperature environment, especially in the process of periodic freezing and thawing cycle, the building structure is vulnerable to damage. Therefore, the building materials of the cold storage and the construction of each part of the cold storage should have enough frost resistance.

In general, the cold storage building is to ensure the quality of the building with its strict heat insulation, sealing, firmness and frost resistance.

4、 The structure of assembled cold storage and the requirements of users for cold storage

1. Length × width × height = volume of cold storage

2. Temperature in the warehouse: fresh-keeping: + 5-5 ℃, cold storage: 0-18 ℃, low temperature: - 18-30 ℃. The thickness of the Library plate

3. Specification and dimension of warehouse door: the required opening direction of wide × high door lock

4. The storage capacity of cold storage and daily purchase and shipment capacity

5. The refrigerator is air-cooled or water-cooled. The refrigeration machine is an air-cooled type. Users only need to choose the location. The chiller is water-cooled, and the user also needs to configure: the specification and size of the water pool, length × width × height = _______

6. Configuration of evaporator: ceiling cooling fan, floor cooling fan or exhaust type________

5、 Auxiliary facilities that users must complete

1. Install a 250px stone filling layer for the foundation of the cold storage, and then pour 5-250px concrete. The ground must be level. Expansion joints or ventilation pipes shall be reserved on the ground of the cold storage to prevent the cold storage foundation from being affected by the low temperature and the volume expansion after the ground is frozen, resulting in the ground fracture and the whole cold storage structure deformation.

2. According to the load capacity of the vehicles in and out (except for people in and out), the floor of the cold storage should be waterproof and heat insulated, and should also be reinforced. The steel mesh should be laid with φ 10-φ 14 rib steel, and 10-625px thick concrete should be poured.

3. Select the users of the water-cooled refrigerator, drill a deepwater well or build a water pool near the refrigerator according to the requirements of the manufacturer, and lay a circulating water pipe to connect to the cooling tower and the location of the unit

4. The power supply (three-phase four-wire) meeting the requirements of the cold storage shall be configured to lead the power supply to the side of the cold storage and be equipped with a special safety switch.

6、 How to choose suitable PU panel cold room

1. The size (length × width × height) of the refrigerator door shall be determined according to the tonnage of the self stored goods, the daily incoming and outgoing quantity and the size of the building. The installation environment of the refrigerator in the opening direction of the door shall be clean, dry and ventilated.

2. According to the stored items, the temperature preservation and storage in the warehouse shall be determined to be + 5-5 ℃, refrigeration, and freezing: 0-18 ℃, low-temperature storage: - 18-30 ℃).

3. According to the characteristics of their own buildings and local water sources, choose the refrigeration mode of the refrigerator, generally air-cooled and water-cooled. (for air-cooled users, they only need to choose the location. For water-cooled users, they also need to configure the location of the water pool or deep well, circulating water pipe, water pump and cooling tower.).