Features and application of cold room evaporator

Jan 09, 2020|

Jan 09, 2020| View:286

View:286Introduction

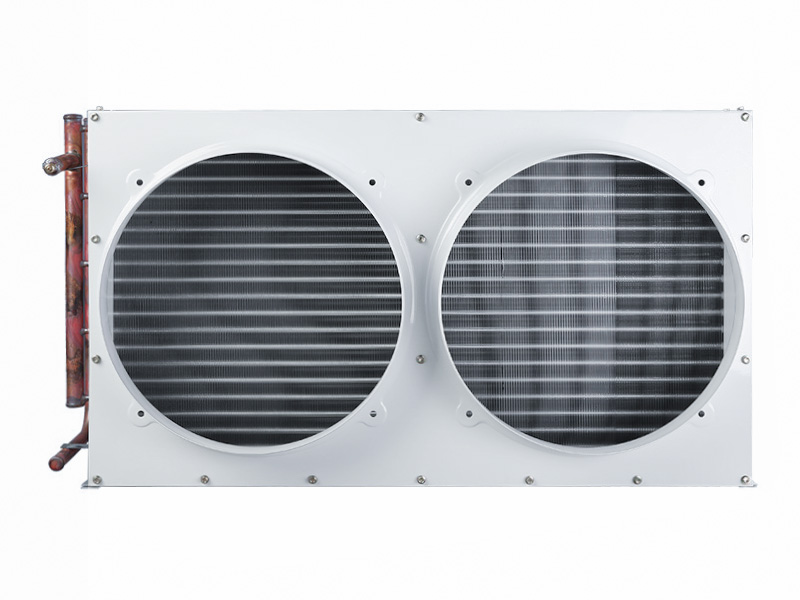

Cold room evaporator as one of the four refrigeration components, the evaporator plays an important role in the whole refrigeration system, so only a reasonable match between the compressor and the evaporator can make the whole refrigeration system play a better role, so the selection and matching of the cold room evaporator is very important in the whole refrigeration system.

Application analysis

The two most common evaporators in the cold storage are the cold fan and the exhaust pipe. The actual cold fan and the exhaust pipe have their own advantages and disadvantages

1. Enclosure

Whether the cold storage adopts civil engineering or steel structure, the bearing of the top should be considered, which is called suspension load in design. When the seamless steel pipe is used to make the exhaust pipe, the reference value of the design suspension load is 70-80kg / m2; if the aluminum alloy pipe is used as the top exhaust pipe, the reference value of the design suspension load is 40-50kg / m2; if the cooling fan is used, only the suspension load of the cooling fan needs to be considered locally.

2. Refrigerant charge

The floor area of the cooling fan is small and the content product is relatively small, so the fluorine capacity of the cooling fan accounts for a small proportion in the whole refrigeration system; the pipe diameter of the exhaust pipe generally varies from Φ 22 to Φ 38, and the larger the pipe diameter, the more the fluorine capacity of the whole refrigeration system increases.

Generally, two to four times more Freon is added to the exhaust pipe shop than to the fan shop. In the form of rising Freon price and upgrading freon, the cost of Freon can not be ignored.

3. Initial investment

In the selection of evaporator alone, the initial investment of aluminum exhaust pipe is generally greater than that of air cooler. The overall cost of the system with a cooling fan is 15% - 25% lower than that of the system with the aluminum exhaust pipe, and the larger the system, the more obvious the difference between the two. Generally, the construction period of the production and hoisting of the exhaust pipe is 3-4 times higher than that of the installation of the cooling fan, so the labor cost for the production and installation of the exhaust pipe is much higher than that for the installation of the cooling fan. In developed countries, cold air fans are used for cooling in cold storage. On the one hand, this factor is also taken into account (labor cost in foreign countries is much higher than that in China).

4. Defrosting method

At present, the common defrosting methods of cold air blowers in cold storage are natural defrosting, water washing defrosting, electric defrosting and hot fluorine defrosting. It is easy to realize the automatic defrosting of the cooling fan. The defrosting water flows to the outside of the cold storage along with the defrosting downpipe of the cooling fan. Hot fluorine defrosting is widely used in aluminum alloy pipes, but the water drops will fall when the pipes are distributed in the warehouse. Therefore, when defrosting, the goods should be generally transferred or covered with waterproof plastic cloth, which is not as flexible and convenient as the defrosting of a cold fan.

5. Later electricity consumption

Under the same other conditions, the forced convection of the cooling fan relies on the motor-driven fan to work and the defrosting of the cooling fan once or twice a day needs to produce a certain amount of power consumption; for the exhaust pipe, the exhaust pipe belongs to natural convection, generally the exhaust pipe is defrosted twice a year, and the aluminum exhaust pipe is relatively less than the cooling fan in terms of the later power consumption.

6. Cold storage capacity

The cooling fan belongs to forced convection, and the cooling speed is fast; the aluminum exhaust pipe belongs to natural convection, and the cooling speed is relatively slow. So in the actual operation of the cold storage, if the matching of the main refrigeration equipment is basically the same, the start-up time of the cold fan storage and the exhaust pipe storage and the compressor is not much different.

The storage capacity of an aluminum exhaust pipe does not play a significant role in the maintenance of the overall storage temperature. The key role in the maintenance of the storage temperature lies in the enclosure structure and insulation practices of the storage, as well as the storage capacity of goods. Compared with the cold storage structure of single-layer, steel structure, polyurethane sandwich double-sided color steel plate, the operation electricity cost of the cold storage structure with multi-layer and integral polyurethane foam spraying inside the civil frame is much less;

7. Dry consumption of goods

The main influencing factors of dry consumption of goods are temperature difference of heat transfer, wind speed, working time of evaporator and packing method.

Generally speaking, the dry consumption of the goods stored in the cold storage using the air-conditioner is greater than that in the cold storage using the exhaust pipe. However, it should be noted that the main body of dry consumption refers to goods rather than refrigerators or evaporators. Therefore, which evaporator is the most reasonable, the key problem is what kind of goods are stored and how to pack them. It is unnecessary to consider the problem of dry consumption for the goods packed in plastic bags.

8. Capital utilization rate

As mentioned above, there is a gap between the construction cycle of the air cooler and the exhaust pipe. The construction cycle of the exhaust pipe is long and the fund is occupied. The short construction cycle of the air cooler can be put into operation quickly and get the investment return earlier, leading the market. If the cold storage rent is about 3 yuan/day ㎡, the monthly rental return is not a small number.

9. Efficiency and quality stability

The cooling fan is a mature product. It is assembled by professional skilled workers and production lines in the factory, while the assembly level of workers has a great influence on the uniformity of liquid supply of the exhaust pipe. The uniformity of the liquid supply of the cooling fan is relatively good.

The failure point of the cooling fan mainly lies in the motor and electrical components used as the running parts, and the failure rate is greatly reduced by using the products of reputation brand as far as possible; while the exhaust pipe, especially the aluminum alloy exhaust pipe, has high welding process requirements and poor rigidity, so if the welding is not good or the force is uneven during hoisting, the probability of leakage of the exhaust pipe is very high. With more and more attention paid to the safety of the refrigeration system, the quality control of equipment will become more and more standardized, and standardized production and management will become an insurmountable threshold for pipe laying.