Precautions For Cold Room Evaporator

Feb 06, 2020|

Feb 06, 2020| View:195

View:195Precautions For Cold Room evaporator

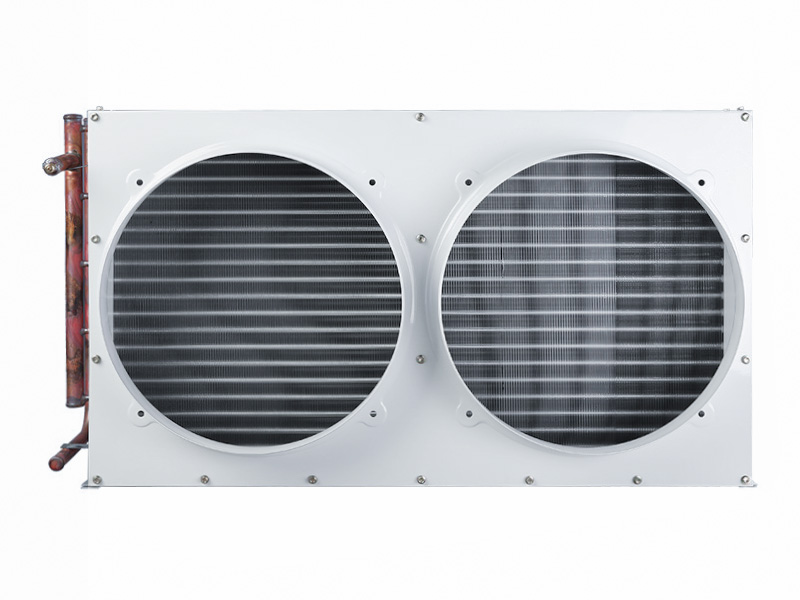

The cold room evaporator can be divided into two types: cooling fan and cooling exhaust pipe. Generally, the cooling fan is used in the cooling room, freezing room and cooling reduction room of cooling materials. Due to different installation positions, it can be divided into floor type cooling fan and ceiling type cooling fan. The cooling pipe is usually used in the freezing room, and the evaporator is also used in the small-scale cold storage. So what are the precautions for evaporator operation in cold storage? Come and have a look!

1 precautions for operation of cooling fan

The cold fan shall be in good condition before starting, the foundation bolts of the fan and the motor shall not be loose, the blades, the protective cover and the air duct shall not be rubbed, the rotation shall be flexible, and the bearing lubrication shall be good.

Before starting the cooling fan, the air return valve of the evaporation coil shall be opened first, and then the liquid supply valve shall be opened. Then turn on the power and start the cooling fan. During operation, it shall be noted that the rotation speed of the fan shall be normal, there shall be no noise during the operation of the fan and motor, the working current of the motor shall not exceed the rated current value, and the temperature of the motor and motor bearing shall not be too high.

During normal operation, the evaporation coil surface of the cooling fan shall be frosted evenly. If it is found that the frosting is not even, it means that the liquid supply is abnormal, it should be adjusted, and the liquid supply valve should be properly opened to increase the liquid supply. If the frost layer is too thick, the fin gap of the evaporation coil will be blocked by the frost layer, which will block the air circulation, reduce the heat exchange efficiency and make it difficult to cool the cold room. Therefore, when the frost is too thick, it should be washed in time. Generally, the cooling fan in the freezing room should be frosted regularly.

When the cooling fan is shut down, the liquid supply valve shall be closed first, and the liquid supply to the evaporation coil of the cooling fan shall be stopped. After the pressure of the evaporation coil drops, the air return valve shall be closed, the power of the fan motor shall be cut off, and the operation of the cooling fan shall be stopped.

2 operation precautions for cooling pipe

The cooling exhaust pipe is the evaporator of natural convection heat exchange of air. Except for the operation without fan, the operation procedure of liquid supply is basically the same as that of cold fan. When the cooling pipe is running, first open the return valve and then slowly open the liquid supply valve to supply liquid to the cooling pipe.

The surface of the cooling pipe should be frosted evenly when the cooling pipe is working normally, and the size of the liquid supply can be determined according to the frosting condition. Too much liquid supply may cause wet stroke of the compressor. Too little liquid supply will not frost the surface of the discharge pipe, which will affect the cooling of the cold room. Therefore, the opening degree of the liquid supply valve should be adjusted regularly according to the actual situation. When the frost is too thick, the cooling pipe should be frosted in time to avoid affecting the heat exchange.

When there is too much oil in the cooling exhaust pipe, the lubricating oil occupies the space of ammonia liquid, and the oil film is formed on the inner wall of the exhaust pipe, which seriously affects the heat exchange and makes it difficult to cool the cooling room. At this time, it is necessary to wash the frost in time to take the oil out of the cooling drain pipe, or discharge it from the specially designed drain pipe to the low-pressure oil collector for treatment.

When the cooling discharge pipe stops running, the liquid supply valve shall be closed first to stop the liquid supply, and the return valve shall be closed after the pressure is reduced.